Eddy Current and Remote Field Eddy Current (RFEC)

Principle

A known energy flux is induced into the material to be tested with an Exciter coil probe by generating a magnetic field which penetrates the material causing eddy currents. Any defects or irregularities in the grain structure disturb the energy flow leading to indications on the oscilloscope.

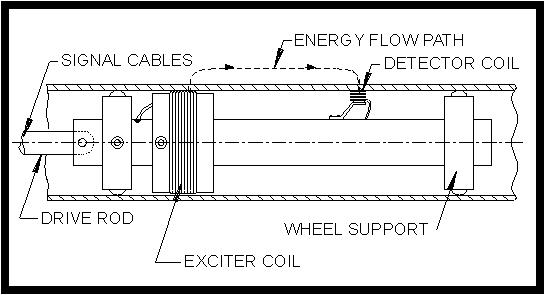

The RFEC tool uses a relatively large internal exciter coil. A detector coil is placed near the inside of the pipe wall, but axially displaced from the exciter by about two pipe Dia. At the outer wall, the field spreads rapidly along the tube with little further attenuation. These fields re-diffuse back through the pipe wall and are the dominant field inside the tube at remote field spacing. Anomalies anywhere in the indirect path cause changes in the magnitude and phase of the received signal, and can therefore be used to detect defects.

Principle of RFEC

Advantages

- Eddy current technique is fast compared to IRIS. Records can be preserved in soft form. Eddy current is suitable for non-ferromagnetic material and RFET is for Ferromagnetic so complete material range is covered.

- Faster Inspection of the tubes is possible, thus requiring lesser downtime.

- No radiation hazard.

Application

Used for scanning and condition assessment of critical exchanger tubes