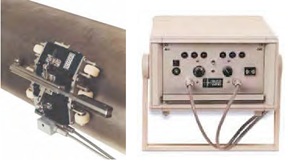

MFL Pipescan Technique

One of a range of fixed or adjustable MFL scaning heads to suit a variety of pipe diameters is moved across the external surface of the pipe and will detect internal and external corrosion pitting. The system includes a separate electronics module with an operator adjustable alarm threshold control. The defect alarm consists of an audible alarm and L.E.D.s.

Inspection using Pipescan

General inspection capabilities

Used as a screening tool, Pipescan is capable of detecting corrosion pitting originating from the internal and/or external surface of the pipe. The system has no sizing capabilities.

nspection limitations

- The longitudinal scanning heads cannot inspect a limited area each side of a circumferential weld or flange. Circumferential scanning heads are available to inspect these areas.

- A limited area adjacent to longitudinal welds is not covered by Pipescan inspections.

- Pipescan scanning heads cannot pass bends / elbows and severely distorted areas of pipe.

- Wall thickness up to 19 mm; coatings up to 6 mm.

- Minimum clearance around pipes: 120 mm.