Pulsed Eddy Current (PEC) Technique

This sheet describes the Pulsed Eddy Current technology as developed and licensed by Shell Global Solutions.

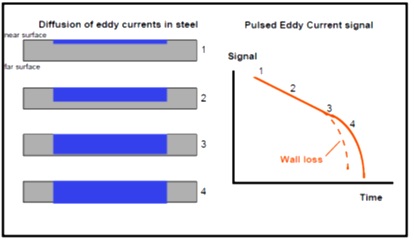

A current pulse is sent through a coil. When the current is interrupted eddy currents are generated in the material, which will decay in time. Measuring the rate of decay of the eddy currents will determine the wall thickness. High wall thickness will result in a slower decay.

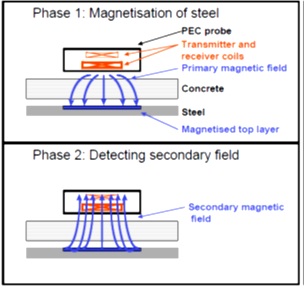

Schematic representation of a PEC measurement. In phase 1, the top layer is magnetised. In phase 2, the secondary field generated by the eddy currents in the steel is detected.

Schematic representation of diffusion of eddy currents in the steel. Initially the currents are concentrated at the surface (stage 1), later the currents diffuse into the steel (stages 2 and 3) until the far end has been reached (stage 4). The decay of the PEC is initially at the same pace but becomes much faster once the far surface has been reached.

General inspection capabilities

Carbon steel or low alloy ferromagnetic metals

• Wall Thickness between 2-35 mm

• Insulation thickness up to 200 mm

• Can detect erosion corrosion, flow accelerated corrosion and corrosion

under insulation

• On stream

• Can measure through any kind of non magnetic insulation (e.g. rockwool,

foamglas, concrete, marine growth, dirt, cladding and scaling)

• Can be applied in wet or underwater conditions

• Measures through aluminium, stainless steel or galvanised (up to 1 mm)

sheeting

• No surface preparation necessary

• The accuracy is roughly 5% of the reference (100%).

• Repeatability on the same spot can be as good as 0.2% in corrosion

monitoring applications.

• A rough rule of thumb is smallest detectable defect diameter is 50% of the liftoff,

i.e. in 50mm of insulation the smallest detectable defect diameter is

around 25mm.

• PEC is a screening tool for inspecting remaining wall thickness under coatings

and insulations. Not considered rapid.

Inspection limitations

• The PEC wall thickness is an average over its ‘footprint’, i.e. the area where

eddy currents flow. The size of the footprint area depends on the distance between probe and metal surface. The footprint is approximately a circle with a diameter depending on the distance between probe and steel surface. The PEC wall thickness readings are an average value over this footprint area. As a result, PEC can only detect general wall loss. Localised corrosion such as pitting is not detected by PEC

• In principle no differentiation between internal and external defects.

• PEC readings depend not only on the thickness of the steel, but also on the electromagnetic properties of the steel, in particular the electrical conductivity and magnetic permeability. These properties depend on steel grade and often vary from one batch of steel to the next. For absolute wall thickness measurements, the PEC instrument must therefore be calibrated on the same object that is inspected, or on the same batch of the steel as the test specimen.

بازرسی حین کار تجهیزات با وجود عایق حرارتی. PEC دارای پروب قابل جابجایی بوده و نیازی به داربست زدن برای بازرسی نمیباشد

بازرسی تجهیزات offshore دارای عایق حین سرویس به کمک نصب توسط زنجیر. بازرسی کامل 2 روز طول میکشد.