Through Transmission Ultrasonic Scanning (AUS)

Principle

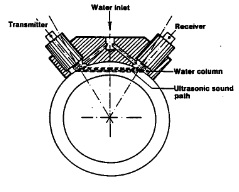

Attenuation and scattering in UT signals are observed, if creep voids and fissures are present in reformer tubes. The amount of scattering is a function of the extent of damage. In this technique, transmitter and receiver ultrasonic probes are fitted in such a manner that the ultrasonic signal passes tangentially through mid-wall of the tubes. An Ultrasonic Flaw Detector measures the loss of signal due to attenuation / scattering

in dB values. Based on the results obtained, the tubes are graded as A, B, C or D in relation to the residual life.

Advantages

- AUS can detect even mild initial stage creep, not detectable by radiography.

- Catalyst unloading is not required to perform AUS unlike radiography (RT), laser profiling (LOTIS) and Eddy Current Testing (ECT) .

- Faster Inspection of the tubes is possible, thus requiring lesser downtime.

- Noradiation hazard.

Principle AUS

Application

In service defects in reformer tubes are originated in the form of Creep voids coalesce to form mid-wall fissures. Theses subsequently propagate as cracks to inner outer surface. AUS is the best suitable and most widely used technique for detection of above defects at early stage. Licensors like HTAS and Linde recommend a frequency of 2 years or less for such examination depending upon tube grading and operating severity.