ThruVu Technique

Direct digital gamma radiography using collimated source and linear array of solid-state sensors. Special software gives on-line display of wall thickness.

General inspection capabilities

A two-dimensional image is displayed, whose intensity is proportional to the wall thickness, thus indicating corrosion and/or erosion on both outside and inside walls.

Can be used to inspect insulated and uninsulated pipework of 6” to 36” diameter.

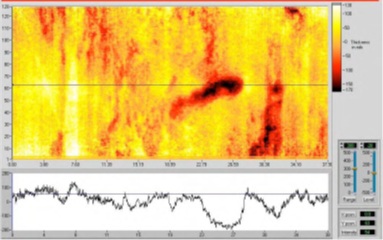

Typical ThruVU Display. The dark areas in the image represent corrosion.

The graph below the image shows a cross-section of the pipe wall through the

corroded area.

Inspection limitations

- Basic system designed for horizontal pipelines. A rail-mounted system has been developed which can be used on horizontal or vertical pipework and elbows.

- The length of the delivery tube on the source container dictates the maximum length that can be covered in a single scan. This is normally of the order of 6m(20′).

- Although source is collimated, radiation exclusion zone is still required.

- Dead zone at each pipe support; the pipe can be examined to within 50mm of the support on the leading edge but only to within 150mm on the trailing edge.

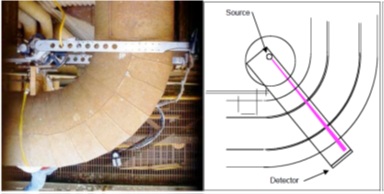

ISwT Rail Mounted Scanner

Elbow Inspection using Rail-mounted System

Access requirements

Low intensity Ir 192 isotope sits on one side of the pipe with an array of solid state detectors situated on the other.

Rail-mounted system requires minimum clearance of 300mm on the source side of the pipe, 100mm on the opposite (detector) side, and 25mm lateral clearance.

Access is required at some location on the pipe to mount the rails and attach the detector.

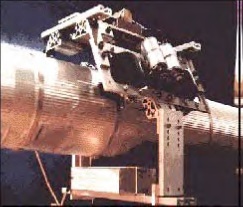

Omega crawler on 4″ insulated pipe

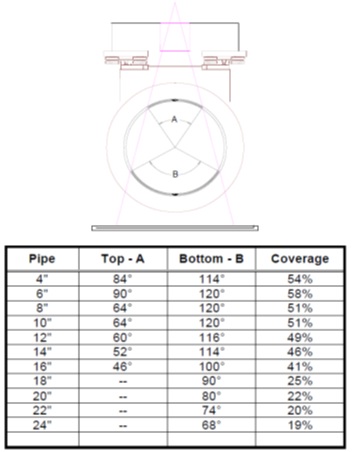

Percentage coverage as function of pipe diameter