Verkade Ultrasonic CUS Technique

Corrosion to the underside of pipelines occurs when the pipe moves due to changing temperatures during operation. Frictional forces between the pipe and support cause the removal of paint and in the presence of water corrosion is produced.

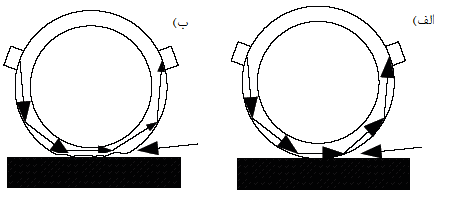

Corrosion underneath supports (CUS) can be monitored using ultrasonic techniques (UT) involving a transmitter at one end of the pipe and a receiver at the other. The ultrasonic beam is applied in a circumferential direction in the pipe, and the resultant beam received by the detector. In the event of no defect being present the received signal will be strong and produce a wave relative to its strength on the operators screen. Should a defect be encountered the ultrasonic wave is reflected in various directions, with only an attenuated signal received, thus producing a much smaller wave on the operator’s screen.

a.Wave Path Without Defect Present b.Wave Path With Defect Present – Signal is Attenuated

General inspection capabilities

- On surfaces with temperatures up to 60 ºC (140 ºF).

- Pipe diameters from 1” to 48” (The test depth is dependant on the permeabilityof the pipe surface as well as the condition of the surface coating.)

- Sensitivity of the measurement process can be adjusted as required.

- Thickness, corrosion depth, and the location of the defect can be found using the system.

Inspection limitations

- Temperatures up to 60 ºC (140 ºF).

- Investigation process can be difficult due to factors such as inside corrosion or inclusions.