Magnetic Flux Leakage(MFL) Inspection Technique

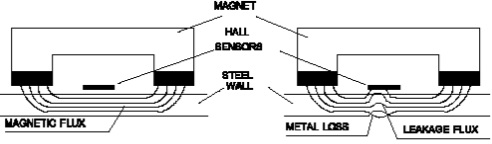

A magnetic field is induced in the component being tested. In defect-free material, this field remains trapped within the material. Changes in material properties or geometry (i.e. defects) force the magnetic field to leak out of the material, where it is detected by the Hall-Effect MFL sensors.

Principle of MFL to detect defect

General inspection capabilities

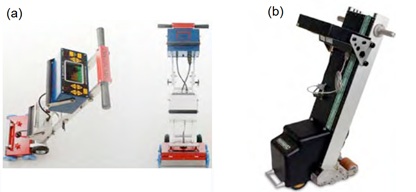

MFL is a screening technique and is popular for inspection of floor and wallsof aboveground storage tanks. MFL is also used for inspection of ferritic tubes.

MFL can detect corrosion, particularly pitting, in materials up to 20 mm thick.

Inspection through non-conducting coating (upto 6 mm thick).

Testing speed: 0.5m/ sec

Testing sensitivity: 20% underfloor corrosion (as per supplier).

Also suitable for ferritic vessels, pipes, boiler tubes, heat exchanger tubes.

Inspection limitations

- MFL is a qualitative technique and requires use of ultrasound for estimation of wall loss and proof up.

- Cannot differentiate between top side and bottom side corrosion.

- Erosion defects may not be detected as the change between full wall thickness and the thinned area is gradual.

- Defect geometry can affect ability to detect defects.

- System sensitivity is affected by scanner speed and surface condition.

- Local changes in permeability can lead to false calls.

MFE Corporation Inc.