Long Range Guided Ultrasonic Wave Technique (Teletest)

Long Range Guided Wave Ultrasonics potentially allows a large volume of pipework to be inspected from a single transducer position.

An array of piezoelectric transducers is clamped around the pipe and an ultrasound signal is sent in both directions along the pipe allowing for 100% volumetric screening of the pipe wall.

Ultrasonic transducers send a symmetrical wave of ultrasound energy axially along the length of the pipe, features generate a series of reflections of this sound which are detected at the tool. A feature with a symmetrical change in wall thickness such as a weld generates a symmetrical reflected signal, whereas a localised thickness change causes a flexural signal to be returned which is recorded differently.

Secondary inspection should be carried out using alternative techniques such as radiography or onventional UT for full quantitive evaluation of potential corrosion areas.

Teletest equipment

The two types of wavemode utilised: Torsional (twisting of the pipe) and Longituninal

(compression of the pipe)

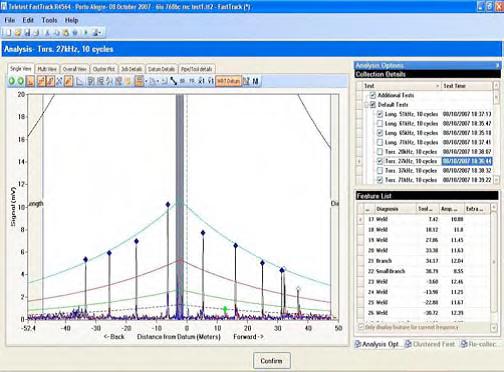

Teletest Software showing Distance Amplitude Correction (DAC) curve

used for analysis.

General inspection capabilities

- Has multimode capability, providing both longitudinal and torsional inspectionsimultaneously.

- Focussing capability for evaluating the distribution of the suspected corrosionaround the pipe.

- Rapid inspection of both internal and external corrosion on long pipe sections.

- Guided waves systems can typically detect most metal loss and cracks > 5%

- cross-sectional area depending on given conditions.

- Reliable detection is 9% cross sectional area loss defects according to the supplier.

- Most suitable for inspection of welded long (greater than 6m) lengths, straight, featureless (limited T-pieces, bends and flanges) pipe work.

- Guided waves are suitable for use on ASME schedule pipe diameters from 38 mm (1.5″) to 1200 mm (48”). Equipment for other pipe sizes is available on request.

- Wall thicknesses up to 80mm (1.6″) have been inspected.

- No couplant is required.

- Inspectable Materials include: C and CMn steels, Austenitic stainless steels, Duplex stainless steels

- Types of Pipe: Seamless, Longitudinally welded, Spiral welded

- Coatings: Polyurethane foam insulation, Mineral wool insulation, Epoxy coated, Tar epoxy coated, PVC coated, Painted. Generally, thicker and denser coatings can effect the expected inspection length.

- In general, a range of 60m (30m in each direction) is a reasonable expectation.

- Under ideal conditions up to 350 metres of pipework has been inspected from a single location. The length of pipe that can be inspected is heavily dependant on several factors including number of features, coating and contents.

Operating Temperature

+5°C to +125°C.

Inspection limitations

- Direct access to 0.5m of pipe is required at the test location .

- The method cannot inspect through flanges Standard practice is to only inspect past one bend at a time. Best practise is to inspect into one bend and then reinspect back to the bend from the otherside. It is possible to inspect around one bend if it is not too tight like a tight elbow. This is dependent on the noise level beyond the bend.

- High viscosity pipe contents (for example hydrocarbons) can attenuate the signal and therefore could be difficult to inspect.

- Coated pipes can be difficult to inspect. Generally thicker and denser coatings are more attenuative however coating condition and bond nature are important.

- The best application of the technique is on above-ground long, relatively

featureless, un-flanged lengths of pipe.

Access requirements

Direct access to the pipe is required to mount the collar

Approximately 100mm clearance around pipes to attach ring transducers

Parameters affecting inspections capabilities

- Type of coating utilised on pipe

- Viscosity of pipe content will affect inspectability

- Pipe geometries